The project aims to develop a method that will speed up the analysis of diffraction patterns that arise in UV and soft X-ray light microscopy, so that the structure of the studied sample can be calculated more efficiently. The method could make the three-dimensional study of nanomaterials considerably easier.

There are times when researchers need to study not only the surface of materials under the microscope, but also their three-dimensional structure. For example, it is crucial to know the exact composition of the nanoparticles used in battery research. In addition to the spatial distribution of functional materials, for example, it is important to know about air pores that give the various components room to expand when they are heated. However, the trouble is that classical microscopy, which works with visible light, does not achieve high enough resolution of these tiny structures. And, while electron microscopy in turn delivers the resolution, it does not deliver three-dimensional results. “We now want to close the gap between these two established methods because a number of important functionalities are still lacking for their practical application – above all, fast data analysis,” says Dr. Jan Rothhardt of the Helmholtz Institute Jena.

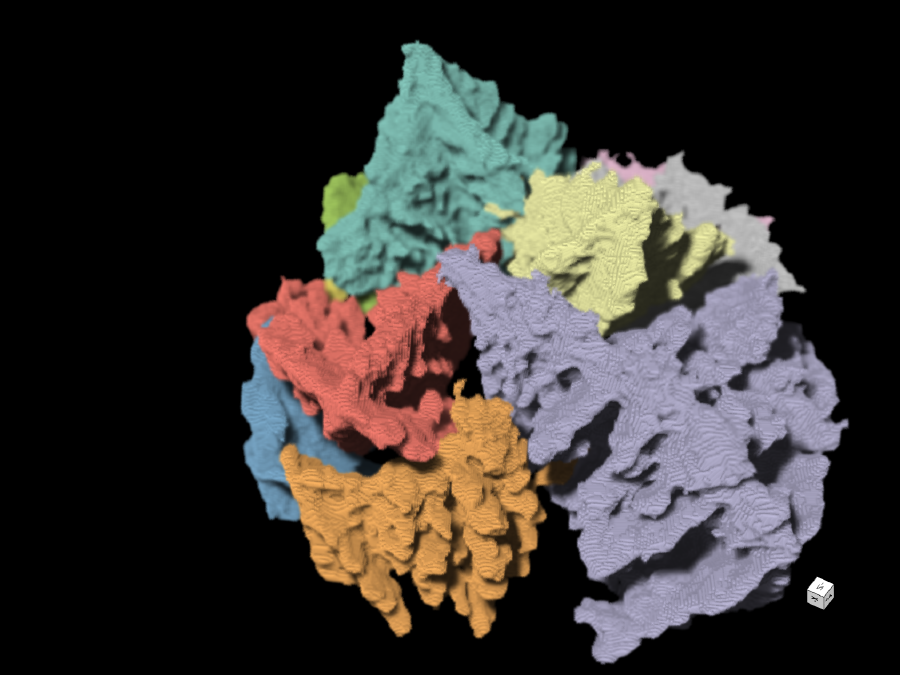

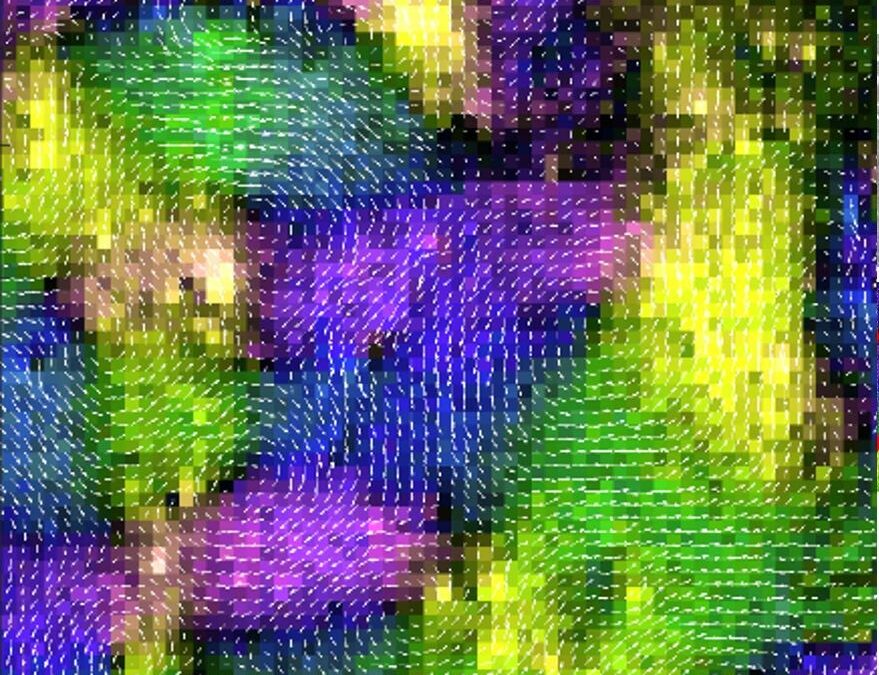

He and his colleagues are therefore working with short-wave beams, in both the extreme ultraviolet and the soft X-ray ranges. “The advantage of these is that they penetrate through objects, so you can see into their volume; but there are no lenses that will work with them,” Rothhardt explains. In other words, lenses are unable to resolve the light beams into the required high resolution images; yet, the beams do produce an abstract diffraction pattern, which can be captured by sensors instead. Once captured, a high performance computer is used to calculate the structure of the studied sample from this pattern – and, so far, this takes many hours of computing time. In the project, they now aim to develop methods for fast data capture and analysis that will significantly accelerate the entire imaging process.

Publications

4725570

ASoftXM

1

https://helmholtz-imaging.de/apa-bold-title.csl

50

date

desc

83

https://helmholtz-imaging.de/wp-content/plugins/zotpress/

%7B%22status%22%3A%22success%22%2C%22updateneeded%22%3Afalse%2C%22instance%22%3Afalse%2C%22meta%22%3A%7B%22request_last%22%3A0%2C%22request_next%22%3A0%2C%22used_cache%22%3Atrue%7D%2C%22data%22%3A%5B%7B%22key%22%3A%2232L3MEKP%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Molina%20et%20al.%22%2C%22parsedDate%22%3A%222023-07-31%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BMolina%2C%20D.%20S.%20P.%2C%20Loetgering%2C%20L.%2C%20Eschen%2C%20W.%2C%20Limpert%2C%20J.%2C%20%26amp%3B%20Rothhardt%2C%20J.%20%282023%29.%20%26lt%3Bb%26gt%3BBroadband%20ptychography%20using%20curved%20wavefront%20illumination%26lt%3B%5C%2Fb%26gt%3B.%20%26lt%3Bi%26gt%3BOptics%20Express%26lt%3B%5C%2Fi%26gt%3B%2C%20%26lt%3Bi%26gt%3B31%26lt%3B%5C%2Fi%26gt%3B%2816%29%2C%2026958%26%23x2013%3B26968.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.495197%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.495197%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Broadband%20ptychography%20using%20curved%20wavefront%20illumination%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Daniel%20S.%20Penagos%22%2C%22lastName%22%3A%22Molina%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Lars%22%2C%22lastName%22%3A%22Loetgering%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Wilhelm%22%2C%22lastName%22%3A%22Eschen%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jens%22%2C%22lastName%22%3A%22Limpert%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jan%22%2C%22lastName%22%3A%22Rothhardt%22%7D%5D%2C%22abstractNote%22%3A%22We%20examine%20the%20interplay%20between%20spectral%20bandwidth%20and%20illumination%20curvature%20in%20ptychography.%20By%20tailoring%20the%20divergence%20of%20the%20illumination%2C%20broader%20spectral%20bandwidths%20can%20be%20tolerated%20without%20requiring%20algorithmic%20modifications%20to%20the%20forward%20model.%20In%20particular%2C%20a%20strong%20wavefront%20curvature%20transitions%20a%20far-field%20diffraction%20geometry%20to%20an%20effectively%20near-field%20one%2C%20which%20is%20less%20affected%20by%20temporal%20coherence%20effects.%20The%20relaxed%20temporal%20coherence%20requirements%20allow%20for%20leveraging%20wider%20spectral%20bandwidths%20and%20larger%20illumination%20spots.%20Our%20findings%20open%20up%20new%20avenues%20towards%20utilizing%20pink%20and%20broadband%20beams%20for%20increased%20flux%20and%20throughput%20at%20both%20synchrotron%20facilities%20and%20lab-scale%20beamlines.%22%2C%22date%22%3A%222023%5C%2F07%5C%2F31%22%2C%22section%22%3A%22%22%2C%22partNumber%22%3A%22%22%2C%22partTitle%22%3A%22%22%2C%22DOI%22%3A%2210.1364%5C%2FOE.495197%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Fabstract.cfm%3Furi%3Doe-31-16-26958%22%2C%22PMID%22%3A%22%22%2C%22PMCID%22%3A%22%22%2C%22ISSN%22%3A%221094-4087%22%2C%22language%22%3A%22EN%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T07%3A47%3A17Z%22%7D%7D%2C%7B%22key%22%3A%22BJSCNAR5%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Melnyk%22%2C%22parsedDate%22%3A%222022-12-09%22%2C%22numChildren%22%3A3%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BMelnyk%2C%20O.%20%282022%29.%20%26lt%3Bi%26gt%3B%26lt%3Bb%26gt%3B%26lt%3Bspan%20style%3D%26quot%3Bfont-style%3Anormal%3B%26quot%3B%26gt%3BStochastic%20Amplitude%20Flow%20for%20phase%20retrieval%2C%20its%20convergence%20and%20doppelg%5C%5C%26quot%3Bangers%26lt%3B%5C%2Fspan%26gt%3B%26lt%3B%5C%2Fb%26gt%3B%26lt%3B%5C%2Fi%26gt%3B%20%28arXiv%3A2212.04916%29.%20arXiv.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2212.04916%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2212.04916%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22preprint%22%2C%22title%22%3A%22Stochastic%20Amplitude%20Flow%20for%20phase%20retrieval%2C%20its%20convergence%20and%20doppelg%5C%5C%5C%22angers%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Oleh%22%2C%22lastName%22%3A%22Melnyk%22%7D%5D%2C%22abstractNote%22%3A%22In%20this%20paper%2C%20we%20focus%20on%20Stochastic%20Amplitude%20Flow%20%28SAF%29%20for%20phase%20retrieval%2C%20a%20stochastic%20gradient%20descent%20for%20the%20amplitude-based%20squared%20loss.%20While%20the%20convergence%20to%20a%20critical%20point%20of%20%28nonstochastic%29%20Amplitude%20Flow%20is%20well-understood%2C%20SAF%20is%20a%20much%20less%20studied%20algorithm.%20We%20close%20this%20gap%20by%20deriving%20the%20convergence%20guarantees%20for%20SAF%20based%20on%20the%20contributions%20for%20Amplitude%20Flow%20and%20analysis%20for%20stochastic%20gradient%20descent.%20These%20results%20are%20then%20applied%20to%20two%20more%20algorithms%2C%20which%20can%20be%20seen%20as%20instances%20of%20SAF.%20The%20first%20is%20an%20extension%20of%20the%20Kaczmarz%20method%20for%20phase%20retrieval.%20The%20second%20is%20Ptychographic%20Iterative%20Engine%2C%20which%20is%20a%20popular%20algorithm%20for%20ptychography%2C%20a%20special%20case%20of%20phase%20retrieval%20with%20the%20short-time%20Fourier%20transform.%20Keywords%3A%20phase%20retrieval%2C%20Amplitude%20Flow%2C%20stochastic%20gradient%20descent%2C%20ptychography%2C%20Ptychographic%20Iterative%20Engine%2C%20Kaczmarz%20method.%22%2C%22genre%22%3A%22%22%2C%22repository%22%3A%22arXiv%22%2C%22archiveID%22%3A%22arXiv%3A2212.04916%22%2C%22date%22%3A%222022-12-09%22%2C%22DOI%22%3A%2210.48550%5C%2FarXiv.2212.04916%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22http%3A%5C%2F%5C%2Farxiv.org%5C%2Fabs%5C%2F2212.04916%22%2C%22language%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T12%3A36%3A11Z%22%7D%7D%2C%7B%22key%22%3A%22SGWQYIQL%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Filbir%20and%20Melnyk%22%2C%22parsedDate%22%3A%222022-10-04%22%2C%22numChildren%22%3A3%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BFilbir%2C%20F.%2C%20%26amp%3B%20Melnyk%2C%20O.%20%282022%29.%20%26lt%3Bi%26gt%3B%26lt%3Bb%26gt%3B%26lt%3Bspan%20style%3D%26quot%3Bfont-style%3Anormal%3B%26quot%3B%26gt%3BImage%20Recovery%20for%20Blind%20Polychromatic%20Ptychography%26lt%3B%5C%2Fspan%26gt%3B%26lt%3B%5C%2Fb%26gt%3B%26lt%3B%5C%2Fi%26gt%3B%20%28arXiv%3A2210.01626%29.%20arXiv.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2210.01626%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2210.01626%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22preprint%22%2C%22title%22%3A%22Image%20Recovery%20for%20Blind%20Polychromatic%20Ptychography%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Frank%22%2C%22lastName%22%3A%22Filbir%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Oleh%22%2C%22lastName%22%3A%22Melnyk%22%7D%5D%2C%22abstractNote%22%3A%22Ptychography%20is%20a%20lensless%20imaging%20technique%2C%20which%20considers%20reconstruction%20from%20a%20set%20of%20far-field%20diffraction%20patterns%20obtained%20by%20illuminating%20small%20overlapping%20regions%20of%20the%20specimen.%20In%20many%20cases%2C%20a%20distribution%20of%20light%20inside%20the%20illuminated%20region%20is%20unknown%20and%20has%20to%20be%20estimated%20along%20with%20the%20object%20of%20interest.%20This%20problem%20is%20referred%20to%20as%20blind%20ptychography.%20While%20in%20ptychography%20the%20illumination%20is%20commonly%20assumed%20to%20have%20a%20point%20spectrum%2C%20in%20this%20paper%20we%20consider%20an%20alternative%20scenario%20with%20non-trivial%20light%20spectrum%20known%20as%20blind%20polychromatic%20ptychography.%20Firstly%2C%20we%20show%20that%20non-blind%20polychromatic%20ptychography%20can%20be%20seen%20as%20a%20recovery%20from%20quadratic%20measurements.%20Then%2C%20a%20reconstruction%20from%20such%20measurements%20can%20be%20performed%20by%20a%20variant%20of%20Amplitude%20Flow%20algorithm%2C%20which%20has%20guaranteed%20sublinear%20convergence%20to%20a%20critical%20point.%20Secondly%2C%20we%20address%20recovery%20from%20blind%20polychromatic%20ptychographic%20measurements%20by%20devising%20an%20alternating%20minimization%20version%20of%20Amplitude%20Flow%20and%20showing%20that%20it%20converges%20to%20a%20critical%20point%20at%20a%20sublinear%20rate.%20Keywords%3A%20ptychography%2C%20phase%20retrieval%2C%20blind%2C%20alternating%20minimization%2C%20gradient%20descent.%22%2C%22genre%22%3A%22%22%2C%22repository%22%3A%22arXiv%22%2C%22archiveID%22%3A%22arXiv%3A2210.01626%22%2C%22date%22%3A%222022-10-04%22%2C%22DOI%22%3A%2210.48550%5C%2FarXiv.2210.01626%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22http%3A%5C%2F%5C%2Farxiv.org%5C%2Fabs%5C%2F2210.01626%22%2C%22language%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T08%3A53%3A49Z%22%7D%7D%2C%7B%22key%22%3A%22LG9RXMMQ%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22numChildren%22%3A0%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3B%26lt%3Bb%26gt%3BHigh-speed%20and%20wide-field%20nanoscale%20table-top%20ptychographic%20EUV%20imaging%20and%20beam%20characterization%20with%20a%20sCMOS%20detector%26lt%3B%5C%2Fb%26gt%3B.%20%28n.d.%29.%20Retrieved%20May%2017%2C%202023%2C%20from%20%26lt%3Ba%20class%3D%26%23039%3Bzp-ItemURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Ffulltext.cfm%3Furi%3Doe-31-9-14212%26amp%3Bid%3D529106%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Ffulltext.cfm%3Furi%3Doe-31-9-14212%26amp%3Bid%3D529106%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22webpage%22%2C%22title%22%3A%22High-speed%20and%20wide-field%20nanoscale%20table-top%20ptychographic%20EUV%20imaging%20and%20beam%20characterization%20with%20a%20sCMOS%20detector%22%2C%22creators%22%3A%5B%5D%2C%22abstractNote%22%3A%22%22%2C%22date%22%3A%22%22%2C%22DOI%22%3A%22%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Ffulltext.cfm%3Furi%3Doe-31-9-14212%26id%3D529106%22%2C%22language%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T08%3A48%3A42Z%22%7D%7D%5D%7D

Molina, D. S. P., Loetgering, L., Eschen, W., Limpert, J., & Rothhardt, J. (2023).

Broadband ptychography using curved wavefront illumination.

Optics Express,

31(16), 26958–26968.

https://doi.org/10.1364/OE.495197

Melnyk, O. (2022).

Stochastic Amplitude Flow for phase retrieval, its convergence and doppelg\"angers (arXiv:2212.04916). arXiv.

https://doi.org/10.48550/arXiv.2212.04916

Filbir, F., & Melnyk, O. (2022).

Image Recovery for Blind Polychromatic Ptychography (arXiv:2210.01626). arXiv.

https://doi.org/10.48550/arXiv.2210.01626

High-speed and wide-field nanoscale table-top ptychographic EUV imaging and beam characterization with a sCMOS detector. (n.d.). Retrieved May 17, 2023, from

https://opg.optica.org/oe/fulltext.cfm?uri=oe-31-9-14212&id=529106