Francisco García Moreno holds a material sample in his hand whose structure is somewhat similar to the inside of a loaf of bread: smaller and larger pores lie there close together. But the sample is not bread. It is a metal foam – a material in which the industry has high hopes, as it is not only stable, but also lightweight and capable of absorbing a great deal of energy.

“What we’re doing here and what we’re working with is X-ray tomography of materials,” says García Moreno, a physicist in charge of the “Avanti” project, which Helmholtz-Zentrum Berlin (HZB) is carrying out together with the German Aerospace Center (DLR). So it’s all about three-dimensional digital images from inside materials.

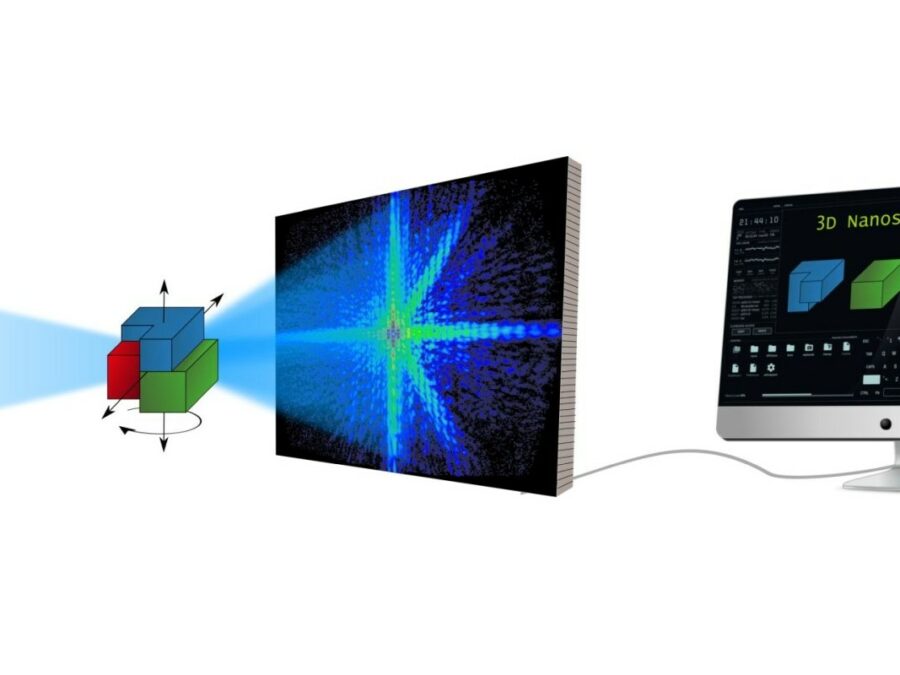

“But we’re not only interested in the structure of solid materials, but also in the details of their manufacturing processes,” García Moreno says. That’s why he and his team members are working with a technique they developed themselves called X-ray tomoscopy (time-resolved tomography). This involves taking X-ray images from all sides at a world-record rate of 1,000 tomograms (3-D images) per second on a high-speed rotating table at a synchrotron light source in Switzerland while a material is being manufactured. For example: while a metal sample is heated to over 600 degrees Celsius until it foams and then cools again.

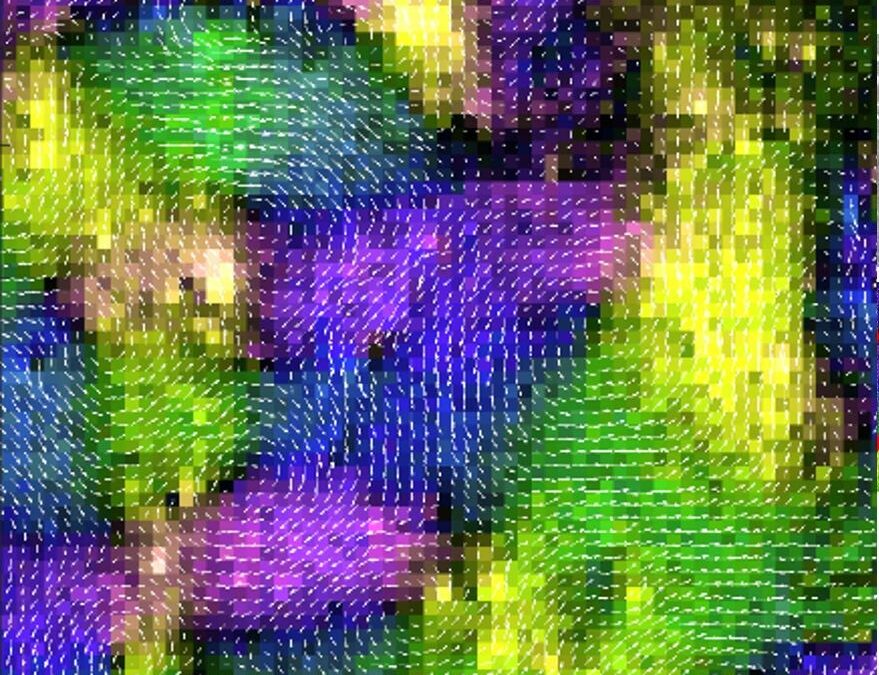

“In this way, we can use the images to observe down to the micrometer where gas bubbles form, how the cell walls develop or in what way the crystal-like dendrites grow when the sample solidifies again,” says García Moreno. This gives them a lot of valuable information about the material and its weak points, and thus about where something needs to be improved.

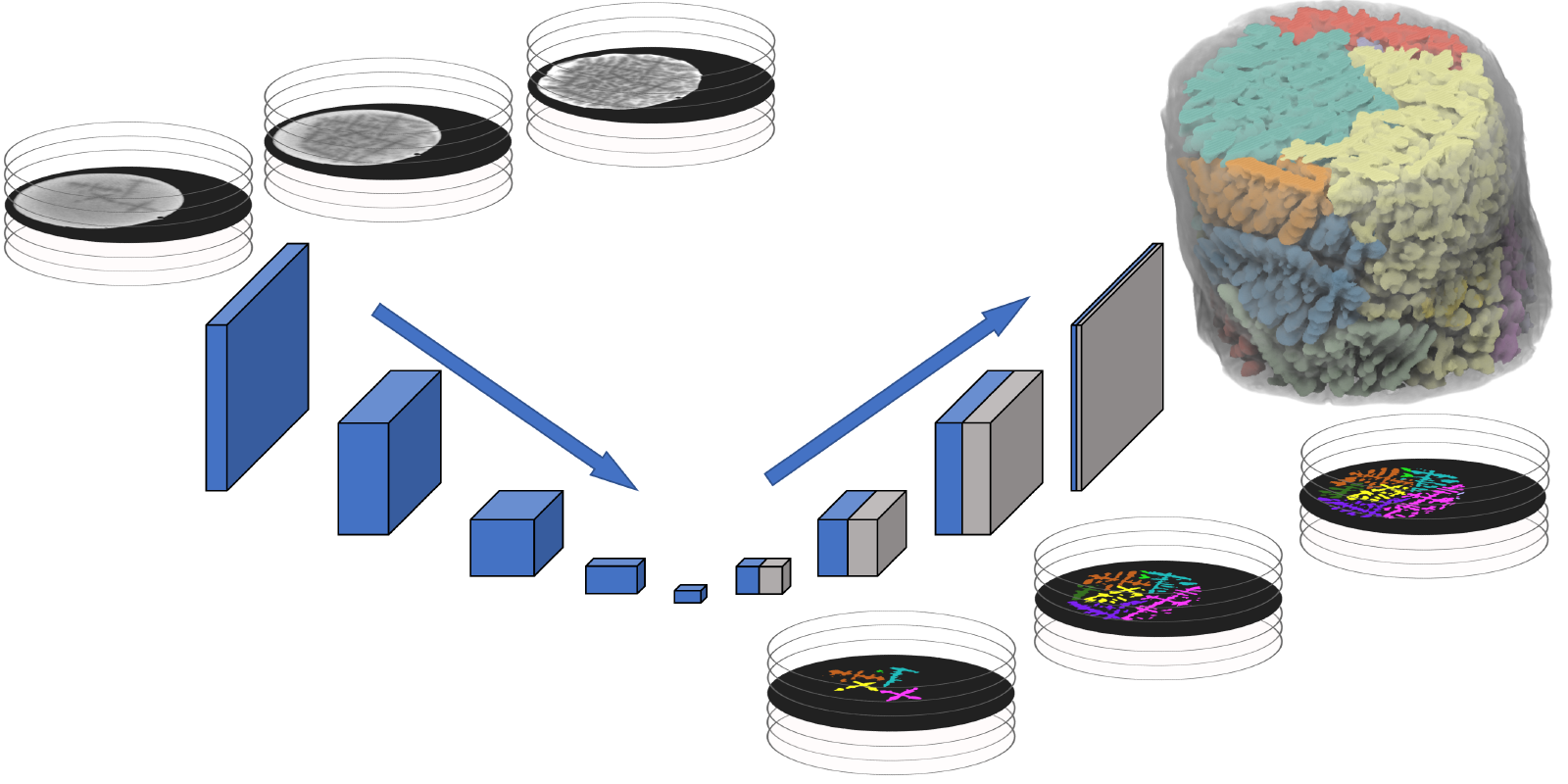

“However, X-ray tomoscopy also gives you an extremely large amount of data,” says Francisco García Moreno. “What’s more, many different features are visible within the material at the same time,” says project partner Prof. Guillermo Requena, who heads the Metallic and Hybrid Materials department at DLR. So if the scientists want to analyze certain features or behaviors of the material – such as the formation of dendrites – they first have to separate them from the other features in order to be able to display and quantify them individually.

Given the enormous volume of images and data generated by the 1,000 tomograms per second, however, this is no longer feasible using conventional image analysis methods. In other words, “We have millions of images in some cases,” says Guillermo Requena. “If we were to process each one individually, we would need years in some cases before we could even get into materials analysis.”

That’s why artificial intelligence comes into play in the “Avanti” project: the scientists train AI systems based on some processed images, namely so-called deep learning algorithms, that they will be able to process the tomograms themselves in the future and display individual features. “This saves us an extremely large amount of time,” says Guillermo Requena. Not only will the materials scientists be able to start their analyses much earlier, but there is also another hope: “Of course, we wish to gain new insights into the materials this way, which we haven’t had before,” says Requena. And not only that: improved tomoscopy could also be increasingly used in other research areas in the future – for example, to observe processes in geology, biology or medicine.

Publications

4725570

Avanti

1

https://helmholtz-imaging.de/apa-bold-title.csl

50

date

desc

902

https://helmholtz-imaging.de/wp-content/plugins/zotpress/

%7B%22status%22%3A%22success%22%2C%22updateneeded%22%3Afalse%2C%22instance%22%3Afalse%2C%22meta%22%3A%7B%22request_last%22%3A0%2C%22request_next%22%3A0%2C%22used_cache%22%3Atrue%7D%2C%22data%22%3A%5B%7B%22key%22%3A%22YM3S2C9Q%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Garc%5Cu00eda-Moreno%20et%20al.%22%2C%22parsedDate%22%3A%222021%22%2C%22numChildren%22%3A2%7D%2C%22bib%22%3A%22%3Cdiv%20class%3D%5C%22csl-bib-body%5C%22%20style%3D%5C%22line-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%5C%22%3E%5Cn%20%20%3Cdiv%20class%3D%5C%22csl-entry%5C%22%3EGarc%26%23xED%3Ba-Moreno%2C%20F.%2C%20Kamm%2C%20P.%20H.%2C%20Neu%2C%20T.%20R.%2C%20B%26%23xFC%3Blk%2C%20F.%2C%20Noack%2C%20M.%20A.%2C%20Wegener%2C%20M.%2C%20von%20der%20Eltz%2C%20N.%2C%20Schlep%26%23xFC%3Btz%2C%20C.%20M.%2C%20Stampanoni%2C%20M.%2C%20%26amp%3B%20Banhart%2C%20J.%20%282021%29.%20%3Cb%3ETomoscopy%3A%20Time-Resolved%20Tomography%20for%20Dynamic%20Processes%20in%20Materials%3C%5C%2Fb%3E.%20%3Ci%3EAdvanced%20Materials%3C%5C%2Fi%3E%2C%20%3Ci%3E33%3C%5C%2Fi%3E%2845%29%2C%202104659.%20%3Ca%20class%3D%27zp-DOIURL%27%20href%3D%27https%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1002%5C%2Fadma.202104659%27%3Ehttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1002%5C%2Fadma.202104659%3C%5C%2Fa%3E%3C%5C%2Fdiv%3E%5Cn%3C%5C%2Fdiv%3E%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Tomoscopy%3A%20Time-Resolved%20Tomography%20for%20Dynamic%20Processes%20in%20Materials%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Francisco%22%2C%22lastName%22%3A%22Garc%5Cu00eda-Moreno%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Paul%20Hans%22%2C%22lastName%22%3A%22Kamm%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Tillmann%20Robert%22%2C%22lastName%22%3A%22Neu%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Felix%22%2C%22lastName%22%3A%22B%5Cu00fclk%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Mike%20Andreas%22%2C%22lastName%22%3A%22Noack%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Mareike%22%2C%22lastName%22%3A%22Wegener%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Nadine%22%2C%22lastName%22%3A%22von%20der%20Eltz%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Christian%20Matthias%22%2C%22lastName%22%3A%22Schlep%5Cu00fctz%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Marco%22%2C%22lastName%22%3A%22Stampanoni%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22John%22%2C%22lastName%22%3A%22Banhart%22%7D%5D%2C%22abstractNote%22%3A%22The%20structure%20and%20constitution%20of%20opaque%20materials%20can%20be%20studied%20with%20X-ray%20imaging%20methods%20such%20as%203D%20tomography.%20To%20observe%20the%20dynamic%20evolution%20of%20their%20structure%20and%20the%20distribution%20of%20constituents%2C%20for%20example%2C%20during%20processing%2C%20heating%2C%20mechanical%20loading%2C%20etc.%2C%203D%20imaging%20has%20to%20be%20fast%20enough.%20In%20this%20paper%2C%20the%20recent%20developments%20of%20time-resolved%20X-ray%20tomography%20that%20have%20led%20to%20what%20one%20now%20calls%20%5Cu201ctomoscopy%5Cu201d%20are%20briefly%20reviewed%20A%20novel%20setup%20is%20presented%20and%20applied%20that%20pushes%20temporal%20resolution%20down%20to%20just%201%20ms%2C%20that%20is%2C%201000%20tomograms%20per%20second%20%28tps%29%20are%20acquired%2C%20while%20maintaining%20spatial%20resolutions%20of%20micrometers%20and%20running%20experiments%20for%20minutes%20without%20interruption.%20Applications%20recorded%20at%20different%20acquisition%20rates%20ranging%20from%2050%20to%201000%20tps%20are%20presented.%20The%20authors%20observe%20and%20quantify%20the%20immiscible%20hypermonotectic%20reaction%20of%20AlBi10%20%28in%20wt%25%29%20alloy%20and%20dendrite%20evolution%20in%20AlGe10%20%28in%20wt%25%29%20casting%20alloy%20during%20fast%20solidification.%20The%20combustion%20process%20and%20the%20evolution%20of%20the%20constituents%20are%20analyzed%20in%20a%20burning%20sparkler.%20Finally%2C%20the%20authors%20follow%20the%20structure%20and%20density%20of%20two%20metal%20foams%20over%20a%20long%20period%20of%20time%20and%20derive%20details%20of%20bubble%20formation%20and%20bubble%20ageing%20including%20quantitative%20analyses%20of%20bubble%20parameters%20with%20millisecond%20temporal%20resolution.%22%2C%22date%22%3A%222021%22%2C%22language%22%3A%22en%22%2C%22DOI%22%3A%2210.1002%5C%2Fadma.202104659%22%2C%22ISSN%22%3A%221521-4095%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fonlinelibrary.wiley.com%5C%2Fdoi%5C%2Fabs%5C%2F10.1002%5C%2Fadma.202104659%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T12%3A39%3A10Z%22%7D%7D%2C%7B%22key%22%3A%22IYBYQQHP%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Energie%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%3Cdiv%20class%3D%5C%22csl-bib-body%5C%22%20style%3D%5C%22line-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%5C%22%3E%5Cn%20%20%3Cdiv%20class%3D%5C%22csl-entry%5C%22%3EEnergie%2C%20H.-Z.%20B.%20f%26%23xFC%3Br%20M.%20und.%20%28n.d.%29.%20%3Cb%3EHZB-Publication%3C%5C%2Fb%3E.%20HZB%20Website.%20Retrieved%20February%2014%2C%202025%2C%20from%20%3Ca%20class%3D%27zp-ItemURL%27%20href%3D%27https%3A%5C%2F%5C%2Fwww.helmholtz-berlin.de%5C%2Fpubbin%5C%2Foai_publication%3FID%3D111886%26typoid%3D76184%27%3Ehttps%3A%5C%2F%5C%2Fwww.helmholtz-berlin.de%5C%2Fpubbin%5C%2Foai_publication%3FID%3D111886%26typoid%3D76184%3C%5C%2Fa%3E%3C%5C%2Fdiv%3E%5Cn%3C%5C%2Fdiv%3E%22%2C%22data%22%3A%7B%22itemType%22%3A%22webpage%22%2C%22title%22%3A%22HZB-Publication%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Helmholtz-Zentrum%20Berlin%20f%5Cu00fcr%20Materialien%20und%22%2C%22lastName%22%3A%22Energie%22%7D%5D%2C%22abstractNote%22%3A%22HZB-Publication%22%2C%22date%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fwww.helmholtz-berlin.de%5C%2Fpubbin%5C%2Foai_publication%3FID%3D111886%26typoid%3D76184%22%2C%22language%22%3A%22de-DE%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T08%3A52%3A25Z%22%7D%7D%5D%7D

García-Moreno, F., Kamm, P. H., Neu, T. R., Bülk, F., Noack, M. A., Wegener, M., von der Eltz, N., Schlepütz, C. M., Stampanoni, M., & Banhart, J. (2021).

Tomoscopy: Time-Resolved Tomography for Dynamic Processes in Materials.

Advanced Materials,

33(45), 2104659.

https://doi.org/10.1002/adma.202104659

Energie, H.-Z. B. für M. und. (n.d.).

HZB-Publication. HZB Website. Retrieved February 14, 2025, from

https://www.helmholtz-berlin.de/pubbin/oai_publication?ID=111886&typoid=76184