It all starts with material samples that are exposed to extremely intense X-rays: At the German Electron Synchrotron (DESY) research centre in Hamburg they are put in the Petra III particle accelerator, which is one of the brightest storage ring-based X-ray radiation sources in the world.

“For the developers of new materials, it is of the greatest interest to determine what their materials look like on the smallest scale”, says Johannes Hagemann, physicist and method developer at DESY, explaining the motivation for such X-ray images. The more precisely developers understand how the microstructures of materials influence their function or when which ageing processes begin, the more efficient and durable materials they can develop.

In a collaborative project between DESY and the Helmholtz Centres in Geesthacht (Hereon), Berlin (HZB) and Dresden-Rossendorf (HZDR), Johannes Hagemann is therefore developing an imaging technique, namely phase contrast imaging, that will make it possible to observe the material samples of new types of batteries, solar cells or even biodegradable implants for bone regeneration in their respective operating state and behaviour already on the nanometre scale and at the same time to record the measurement data intelligently. Together the partners in the project cover all aspects of the problem at hand, ranging from physics, algorithm development, machine learning to the actual beamline and experiments to holistically approach the phase problem.

“Instead of the micrometre scale, which is currently the standard, we would like to make the nanometre scale the standard”, says Hagemann. This is because there is even more information about key processes that control the behaviour of materials. However, if you go into these resolution ranges, extremely large amounts of data must first be processed before the material sample can be displayed as a 3-D image and segmented and quantified together with its components.

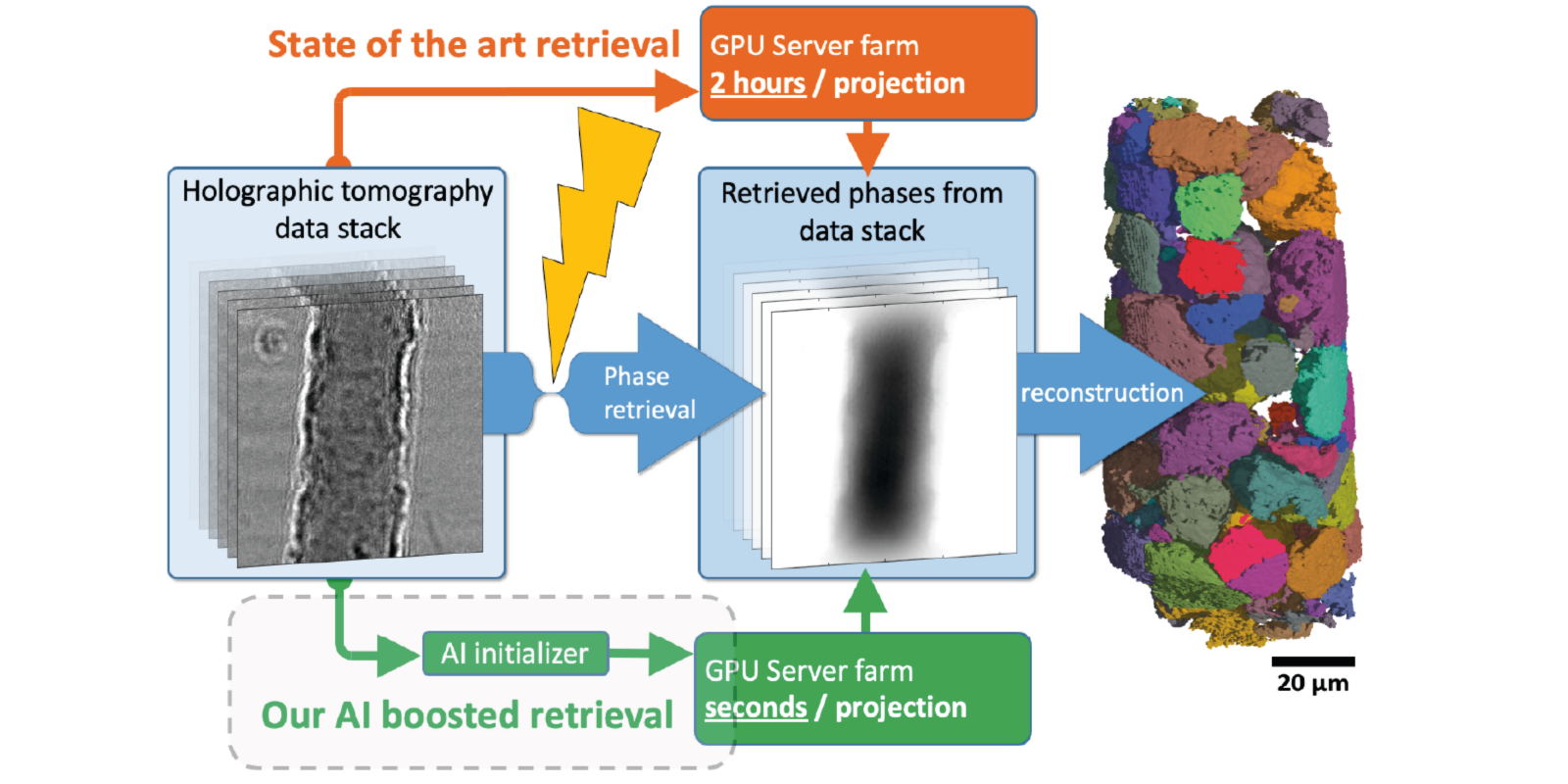

That is why the researchers in this project are working with algorithms, machine learning and neural networks to automate the image reconstruction – without the so-called “human in the loop”, the technical expert who monitors the processes. His intuition must therefore be integrated into the system. The proposed developments shall reduce the required computation time from hours to seconds.

The goal of the project is to have real-time access to the 3-D images of the samples in the future. Why? “So that the material developers already have interpretable images and accurate data available during their experiments”, says Hagemann. “So they can intervene earlier in their experiments – and in this way accelerate the development of newer, more durable materials.” And that in turn: contributes to sustainability.

News articles

Advances in Holographic Image Reconstruction (CONNECT blog post)

Publications

4725570

SmartPhase

1

https://helmholtz-imaging.de/apa-bold-title.csl

50

date

desc

899

https://helmholtz-imaging.de/wp-content/plugins/zotpress/

%7B%22status%22%3A%22success%22%2C%22updateneeded%22%3Afalse%2C%22instance%22%3Afalse%2C%22meta%22%3A%7B%22request_last%22%3A0%2C%22request_next%22%3A0%2C%22used_cache%22%3Atrue%7D%2C%22data%22%3A%5B%7B%22key%22%3A%2289FBVCM5%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Dora%20et%20al.%22%2C%22parsedDate%22%3A%222025-02-24%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BDora%2C%20J.%2C%20M%26%23xF6%3Bddel%2C%20M.%2C%20Flenner%2C%20S.%2C%20Reimers%2C%20J.%2C%20Zeller-Plumhoff%2C%20B.%2C%20Schroer%2C%20C.%20G.%2C%20Knopp%2C%20T.%2C%20%26amp%3B%20Hagemann%2C%20J.%20%282025%29.%20%26lt%3Bb%26gt%3BModel-based%20autofocus%20for%20near-field%20phase%20retrieval%26lt%3B%5C%2Fb%26gt%3B.%20%26lt%3Bi%26gt%3BOptics%20Express%26lt%3B%5C%2Fi%26gt%3B%2C%20%26lt%3Bi%26gt%3B33%26lt%3B%5C%2Fi%26gt%3B%284%29%2C%206641%26%23x2013%3B6657.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.544573%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.544573%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Model-based%20autofocus%20for%20near-field%20phase%20retrieval%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Dora%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Martin%22%2C%22lastName%22%3A%22M%5Cu00f6ddel%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Silja%22%2C%22lastName%22%3A%22Flenner%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jan%22%2C%22lastName%22%3A%22Reimers%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Berit%22%2C%22lastName%22%3A%22Zeller-Plumhoff%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Christian%20G.%22%2C%22lastName%22%3A%22Schroer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Tobias%22%2C%22lastName%22%3A%22Knopp%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Hagemann%22%7D%5D%2C%22abstractNote%22%3A%22The%20phase%20problem%20is%20a%20well%20known%20ill-posed%20reconstruction%20problem%20of%20coherent%20lens-less%20microscopic%20imaging%2C%20where%20only%20the%20intensities%20of%20a%20complex%20wave-field%20are%20measured%20by%20the%20detector%20and%20the%20phase%20information%20is%20lost.%20For%20the%20reconstruction%20of%20sharp%20images%20from%20holograms%20in%20a%20near-field%20experimental%20setting%2C%20it%20is%20crucial%20to%20solve%20the%20autofocus%20problem%2C%20i.e.%2C%20to%20precisely%20estimate%20the%20Fresnel%20number%20of%20the%20forward%20model.%20Otherwise%2C%20blurred%20out-of%20focus%20images%20that%20also%20can%20contain%20artifacts%20are%20the%20result.%20In%20general%2C%20a%20simple%20distance%20measurement%20at%20the%20experiment%20is%20not%20sufficiently%20accurate%2C%20thus%20the%20fine-tuning%20of%20the%20Fresnel%20number%20has%20to%20be%20done%20prior%20to%20the%20actual%20reconstructions.%20This%20can%20be%20done%20manually%20or%20automatically%20by%20an%20estimation%20algorithm.%20To%20automatize%20the%20process%2C%20as%20needed%2C%20e.g.%2C%20for%20in-situ%5C%2Foperando%20experiments%2C%20different%20focus%20criteria%20have%20been%20widely%20studied%20in%20literature%20but%20are%20subjected%20to%20certain%20restrictions.%20The%20methods%20often%20rely%20on%20image%20analysis%20of%20the%20reconstructed%20image%2C%20making%20them%20sensitive%20to%20image%20noise%20and%20also%20neglecting%20algorithmic%20properties%20of%20the%20applied%20phase%20retrieval.%20In%20this%20paper%2C%20we%20propose%20a%20novel%20criterion%2C%20based%20on%20a%20model-matching%20approach%2C%20which%20improves%20autofocusing%20by%20also%20taking%20the%20underlying%20reconstruction%20algorithm%2C%20the%20forward%20model%20and%20the%20measured%20hologram%20into%20account.%20We%20derive%20a%20common%20autofocusing%20framework%2C%20based%20on%20a%20recent%20phase-retrieval%20approach%20and%20a%20downhill-simplex%20method%20for%20the%20automatic%20optimization%20of%20the%20Fresnel%20number.%20We%20further%20demonstrate%20the%20robustness%20of%20the%20framework%20on%20different%20data%20sets%20obtained%20at%20the%20nano%20imaging%20endstation%20of%20P05%20at%20PETRA%20III%20%28DESY%2C%20Hamburg%29%20operated%20by%20Helmholtz-Zentrum%20Hereon.%22%2C%22date%22%3A%222025%5C%2F02%5C%2F24%22%2C%22section%22%3A%22%22%2C%22partNumber%22%3A%22%22%2C%22partTitle%22%3A%22%22%2C%22DOI%22%3A%2210.1364%5C%2FOE.544573%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Fabstract.cfm%3Furi%3Doe-33-4-6641%22%2C%22PMID%22%3A%22%22%2C%22PMCID%22%3A%22%22%2C%22ISSN%22%3A%221094-4087%22%2C%22language%22%3A%22EN%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T09%3A05%3A27Z%22%7D%7D%2C%7B%22key%22%3A%224BAGRMD8%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Kirchner%20et%20al.%22%2C%22parsedDate%22%3A%222025-01-13%22%2C%22numChildren%22%3A3%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BKirchner%2C%20F.%2C%20Wieland%2C%20D.%20C.%20F.%2C%20Irvine%2C%20S.%2C%20Schimek%2C%20S.%2C%20Reimers%2C%20J.%2C%20Aversa%2C%20R.%2C%20Boubnov%2C%20A.%2C%20Lucas%2C%20C.%2C%20Flenner%2C%20S.%2C%20Greving%2C%20I.%2C%20Marinho%2C%20A.%20L.%2C%20Wong%2C%20T.%20M.%2C%20Willumeit-R%26%23xF6%3Bmer%2C%20R.%2C%20Eschke%2C%20C.%2C%20%26amp%3B%20Zeller-Plumhoff%2C%20B.%20%282025%29.%20%26lt%3Bi%26gt%3B%26lt%3Bb%26gt%3B%26lt%3Bspan%20style%3D%26quot%3Bfont-style%3Anormal%3B%26quot%3B%26gt%3BAn%20ontology-based%20description%20of%20nano%20computed%20tomography%20measurements%20in%20electronic%20laboratory%20notebooks%3A%20from%20metadata%20schema%20to%20first%20user%20experience%26lt%3B%5C%2Fspan%26gt%3B%26lt%3B%5C%2Fb%26gt%3B%26lt%3B%5C%2Fi%26gt%3B%20%28arXiv%3A2501.07398%29.%20arXiv.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2501.07398%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.48550%5C%2FarXiv.2501.07398%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22preprint%22%2C%22title%22%3A%22An%20ontology-based%20description%20of%20nano%20computed%20tomography%20measurements%20in%20electronic%20laboratory%20notebooks%3A%20from%20metadata%20schema%20to%20first%20user%20experience%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Fabian%22%2C%22lastName%22%3A%22Kirchner%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22D.%20C.%20Florian%22%2C%22lastName%22%3A%22Wieland%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Sarah%22%2C%22lastName%22%3A%22Irvine%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Sven%22%2C%22lastName%22%3A%22Schimek%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jan%22%2C%22lastName%22%3A%22Reimers%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Rossella%22%2C%22lastName%22%3A%22Aversa%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Alexey%22%2C%22lastName%22%3A%22Boubnov%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Christian%22%2C%22lastName%22%3A%22Lucas%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Silja%22%2C%22lastName%22%3A%22Flenner%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Imke%22%2C%22lastName%22%3A%22Greving%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Andr%5Cu00e9%20Lopes%22%2C%22lastName%22%3A%22Marinho%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Tak%20Ming%22%2C%22lastName%22%3A%22Wong%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Regine%22%2C%22lastName%22%3A%22Willumeit-R%5Cu00f6mer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Catriona%22%2C%22lastName%22%3A%22Eschke%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Berit%22%2C%22lastName%22%3A%22Zeller-Plumhoff%22%7D%5D%2C%22abstractNote%22%3A%22In%20recent%20years%2C%20the%20importance%20of%20well-documented%20metadata%20has%20been%20discussed%20increasingly%20in%20many%20research%20fields.%20Making%20all%20metadata%20generated%20during%20scientific%20research%20available%20in%20a%20findable%2C%20accessible%2C%20interoperable%2C%20and%20reusable%20%28FAIR%29%20manner%20remains%20a%20significant%20challenge%20for%20researchers%20across%20fields.%20Scientific%20communities%20are%20agreeing%20to%20achieve%20this%20by%20making%20all%20data%20available%20in%20a%20semantically%20annotated%20knowledge%20graph%20using%20semantic%20web%20technologies.%20Most%20current%20approaches%20do%20not%20gather%20metadata%20in%20a%20consistent%20and%20community-agreed%20standardized%20way%2C%20and%20there%20are%20insufficient%20tools%20to%20support%20the%20process%20of%20turning%20them%20into%20a%20knowledge%20graph.%20We%20present%20an%20example%20solution%20in%20which%20the%20creation%20of%20a%20schema%20and%20ontology%20are%20placed%20at%20the%20beginning%20of%20the%20scientific%20process%20which%20is%20then%20-%20using%20the%20electronic%20laboratory%20notebook%20framework%20Herbie%20-%20turned%20into%20a%20bespoke%20data%20collection%20platform%20to%20facilitate%20validation%20and%20semantic%20annotation%20of%20the%20metadata%20immediately%20during%20an%20experiment.%20Using%20the%20example%20of%20synchrotron%20radiation-based%20nano%20computed%20tomography%20measurements%2C%20we%20present%20a%20holistic%20approach%20which%20can%20capture%20the%20complex%20metadata%20of%20such%20research%20instruments%20in%20a%20flexible%20and%20straightforward%20manner.%20Different%20instrument%20setups%20of%20this%20beamline%20can%20be%20considered%2C%20allowing%20a%20user-friendly%20experience.%20We%20show%20how%20Herbie%20turns%20all%20semantic%20documents%20into%20an%20accessible%20user%20interface%2C%20where%20all%20data%20entered%20automatically%20fulfills%20all%20requirements%20of%20being%20FAIR%2C%20and%20present%20how%20data%20can%20be%20directly%20extracted%20via%20competency%20questions%20without%20requiring%20familiarity%20with%20the%20fine-grained%20structure%20of%20the%20knowledge%20graph.%22%2C%22genre%22%3A%22%22%2C%22repository%22%3A%22arXiv%22%2C%22archiveID%22%3A%22arXiv%3A2501.07398%22%2C%22date%22%3A%222025-01-13%22%2C%22DOI%22%3A%2210.48550%5C%2FarXiv.2501.07398%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22http%3A%5C%2F%5C%2Farxiv.org%5C%2Fabs%5C%2F2501.07398%22%2C%22language%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T07%3A42%3A03Z%22%7D%7D%2C%7B%22key%22%3A%22X8T48RI6%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Dora%20et%20al.%22%2C%22parsedDate%22%3A%222024-11-01%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BDora%2C%20J.%2C%20Flenner%2C%20S.%2C%20Lopes%20Marinho%2C%20A.%2C%20%26amp%3B%20Hagemann%2C%20J.%20%282024%29.%20%26lt%3Bi%26gt%3B%26lt%3Bb%26gt%3B%26lt%3Bspan%20style%3D%26quot%3Bfont-style%3Anormal%3B%26quot%3B%26gt%3BA%20Python%20framework%20for%20the%20online%20reconstruction%20of%20X-ray%20near-field%20holography%20data%26lt%3B%5C%2Fspan%26gt%3B%26lt%3B%5C%2Fb%26gt%3B%26lt%3B%5C%2Fi%26gt%3B%20%281.3.1%29.%20Zenodo.%20https%3A%5C%2F%5C%2Fdoi.org%5C%2F10.5281%5C%2Fzenodo.14024980%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22computerProgram%22%2C%22title%22%3A%22A%20Python%20framework%20for%20the%20online%20reconstruction%20of%20X-ray%20near-field%20holography%20data%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22programmer%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Dora%22%7D%2C%7B%22creatorType%22%3A%22programmer%22%2C%22firstName%22%3A%22Silja%22%2C%22lastName%22%3A%22Flenner%22%7D%2C%7B%22creatorType%22%3A%22programmer%22%2C%22firstName%22%3A%22Andr%5Cu00e9%22%2C%22lastName%22%3A%22Lopes%20Marinho%22%7D%2C%7B%22creatorType%22%3A%22programmer%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Hagemann%22%7D%5D%2C%22abstractNote%22%3A%22The%20phase%20problem%20is%20a%20well%20known%20ill-posed%20reconstruction%20problem%20of%20coherent%20lens-less%20microscopic%20imaging%2C%20where%20only%20the%20squared%20magnitude%20of%20a%20complex%20wavefront%20is%20measured%20by%20a%20detector%20while%20the%20phase%20information%20from%20the%20wave%20field%20is%20lost.%20To%20retrieve%20the%20lost%20information%2C%20common%20algorithms%20rely%20either%20on%20multiple%20data%20acquisitions%20under%20varying%20measurement%20conditions%20or%20on%20the%20application%20of%20strong%20constraints%20such%20as%20a%20spatial%20support.%20In%20X-ray%20near-field%20holography%20however%2C%20these%20methods%20are%20rendered%20impractical%20in%20the%20setting%20of%20time%20sensitive%20in%20situ%20and%20in%20operando%20measurements.%20In%20this%20framework%2C%20we%20forego%20the%20spatial%20support%20constraint%20and%20propose%20a%20projected%20gradient%20descent%20%28PGD%29%20based%20reconstruction%20scheme%20in%20combination%20with%20proper%20preprocessing%20that%20significantly%20reduces%20artifacts%20for%20refractive%20reconstructions%20from%20only%20a%20single%20acquired%20hologram%20without%20a%20spatial%20support%20constraint.%20This%20repository%20contains%20the%20implementation%20and%20examples%20shown%20in%20the%20paper%20%26quot%3BArtifact-suppressing%20reconstruction%20of%20strongly%20interacting%20objects%20in%20X-ray%20near-field%20holography%20without%20a%20spatial%20support%20constraint%26quot%3B.%5Cu00a0https%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.514641%5Cn%5CnFor%20the%20reconstruction%20of%20sharp%20images%20from%20experimental%20holograms%20in%20the%20near-field%20regime%2C%20it%20is%20crucial%20to%20precisely%20estimate%20the%20Fresnel%20number%20of%20the%20forward%20model.%20Otherwise%2C%20blurred%20out-of%20focus%20images%20that%20also%20can%20contain%20artifacts%20are%20the%20result.%20In%20general%2C%20a%20simple%20distance%20measurement%20at%20the%20experimental%20setup%20is%20not%20sufficiently%20accurate%2C%20thus%20the%20fine-tuning%20of%20the%20Fresnel%20number%20has%20to%20be%20done%20prior%20to%20the%20actual%20phase%20retrieval.%20This%20can%20be%20done%20manually%20or%20automatically%20by%20an%20estimation%20algorithm.%20In%20this%20framework%2C%20we%20propose%20a%20novel%20criterion%2C%20based%20on%20a%20model%20matching%20approach%20with%20respect%20to%20the%20underlying%20reconstruction%20of%20the%20projected%20refractive%20index%20of%20an%20object.%20With%20respect%20to%20this%20criterion%2C%20we%20provide%20a%20downhill-simplex%20method%20for%20the%20automatic%20optimization%20of%20the%20Fresnel%20number.%20This%20approach%20provides%20%5Cu00a0a%20solutIon%20for%20automatic%20focusing%20for%20the%20phase%20retrieval%20of%20near-field%20holograms.%22%2C%22versionNumber%22%3A%221.3.1%22%2C%22date%22%3A%222024-11-01%22%2C%22system%22%3A%22%22%2C%22company%22%3A%22Zenodo%22%2C%22programmingLanguage%22%3A%22%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fzenodo.org%5C%2Frecords%5C%2F14024980%22%2C%22DOI%22%3A%22%22%2C%22ISBN%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-04-30T14%3A37%3A07Z%22%7D%7D%2C%7B%22key%22%3A%22QWZTEL4Y%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Dora%20et%20al.%22%2C%22parsedDate%22%3A%222024-03-25%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BDora%2C%20J.%2C%20M%26%23xF6%3Bddel%2C%20M.%2C%20Flenner%2C%20S.%2C%20Schroer%2C%20C.%20G.%2C%20Knopp%2C%20T.%2C%20%26amp%3B%20Hagemann%2C%20J.%20%282024%29.%20%26lt%3Bb%26gt%3BArtifact-suppressing%20reconstruction%20of%20strongly%20interacting%20objects%20in%20X-ray%20near-field%20holography%20without%20a%20spatial%20support%20constraint%26lt%3B%5C%2Fb%26gt%3B.%20%26lt%3Bi%26gt%3BOptics%20Express%26lt%3B%5C%2Fi%26gt%3B%2C%20%26lt%3Bi%26gt%3B32%26lt%3B%5C%2Fi%26gt%3B%287%29%2C%2010801%26%23x2013%3B10828.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-DOIURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.514641%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1364%5C%2FOE.514641%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Artifact-suppressing%20reconstruction%20of%20strongly%20interacting%20objects%20in%20X-ray%20near-field%20holography%20without%20a%20spatial%20support%20constraint%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Dora%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Martin%22%2C%22lastName%22%3A%22M%5Cu00f6ddel%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Silja%22%2C%22lastName%22%3A%22Flenner%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Christian%20G.%22%2C%22lastName%22%3A%22Schroer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Tobias%22%2C%22lastName%22%3A%22Knopp%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Hagemann%22%7D%5D%2C%22abstractNote%22%3A%22The%20phase%20problem%20is%20a%20well%20known%20ill-posed%20reconstruction%20problem%20of%20coherent%20lens-less%20microscopic%20imaging%2C%20where%20only%20the%20squared%20magnitude%20of%20a%20complex%20wavefront%20is%20measured%20by%20a%20detector%20while%20the%20phase%20information%20of%20the%20wave%20field%20is%20lost.%20To%20retrieve%20the%20lost%20information%2C%20common%20algorithms%20rely%20either%20on%20multiple%20data%20acquisitions%20under%20varying%20measurement%20conditions%20or%20on%20the%20application%20of%20strong%20constraints%20such%20as%20a%20spatial%20support.%20In%20X-ray%20near-field%20holography%2C%20however%2C%20these%20methods%20are%20rendered%20impractical%20in%20the%20setting%20of%20time%20sensitive%20in%20situ%20and%20operando%20measurements.%20In%20this%20paper%2C%20we%20will%20forego%20the%20spatial%20support%20constraint%20and%20propose%20a%20projected%20gradient%20descent%20%28PGD%29%20based%20reconstruction%20scheme%20in%20combination%20with%20proper%20preprocessing%20and%20regularization%20that%20significantly%20reduces%20artifacts%20for%20refractive%20reconstructions%20from%20only%20a%20single%20acquired%20hologram%20without%20a%20spatial%20support%20constraint.%20We%20demonstrate%20the%20feasibility%20and%20robustness%20of%20our%20approach%20on%20different%20data%20sets%20obtained%20at%20the%20nano%20imaging%20endstation%20of%20P05%20at%20PETRA%20III%20%28DESY%2C%20Hamburg%29%20operated%20by%20Helmholtz-Zentrum%20Hereon.%22%2C%22date%22%3A%222024%5C%2F03%5C%2F25%22%2C%22section%22%3A%22%22%2C%22partNumber%22%3A%22%22%2C%22partTitle%22%3A%22%22%2C%22DOI%22%3A%2210.1364%5C%2FOE.514641%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fopg.optica.org%5C%2Foe%5C%2Fabstract.cfm%3Furi%3Doe-32-7-10801%22%2C%22PMID%22%3A%22%22%2C%22PMCID%22%3A%22%22%2C%22ISSN%22%3A%221094-4087%22%2C%22language%22%3A%22EN%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-05-02T07%3A44%3A12Z%22%7D%7D%2C%7B%22key%22%3A%224K5HCLBN%22%2C%22library%22%3A%7B%22id%22%3A4725570%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Reimers%20et%20al.%22%2C%22parsedDate%22%3A%222023-07-26%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%26lt%3Bdiv%20class%3D%26quot%3Bcsl-bib-body%26quot%3B%20style%3D%26quot%3Bline-height%3A%201.35%3B%20padding-left%3A%201em%3B%20text-indent%3A-1em%3B%26quot%3B%26gt%3B%5Cn%20%20%26lt%3Bdiv%20class%3D%26quot%3Bcsl-entry%26quot%3B%26gt%3BReimers%2C%20J.%2C%20Trinh%2C%20H.%20C.%2C%20Wiese%2C%20B.%2C%20Meyer%2C%20S.%2C%20Brehling%2C%20J.%2C%20Flenner%2C%20S.%2C%20Hagemann%2C%20J.%2C%20Kruth%2C%20M.%2C%20Kibkalo%2C%20L.%2C%20%26%23x106%3Bwieka%2C%20H.%2C%20Hindenlang%2C%20B.%2C%20Lipinska-Chwalek%2C%20M.%2C%20Mayer%2C%20J.%2C%20Willumeit-R%26%23xF6%3Bmer%2C%20R.%2C%20Greving%2C%20I.%2C%20%26amp%3B%20Zeller-Plumhoff%2C%20B.%20%282023%29.%20%26lt%3Bb%26gt%3BDevelopment%20of%20a%20Bioreactor-Coupled%20Flow-Cell%20Setup%20for%203D%20In%20Situ%20Nanotomography%20of%20Mg%20Alloy%20Biodegradation%26lt%3B%5C%2Fb%26gt%3B.%20%26lt%3Bi%26gt%3BACS%20Applied%20Materials%20%26amp%3B%20Interfaces%26lt%3B%5C%2Fi%26gt%3B%2C%20%26lt%3Bi%26gt%3B15%26lt%3B%5C%2Fi%26gt%3B%2829%29%2C%2035600%26%23x2013%3B35610.%20%26lt%3Ba%20class%3D%26%23039%3Bzp-ItemURL%26%23039%3B%20href%3D%26%23039%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1021%5C%2Facsami.3c04054%26%23039%3B%26gt%3Bhttps%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1021%5C%2Facsami.3c04054%26lt%3B%5C%2Fa%26gt%3B%26lt%3B%5C%2Fdiv%26gt%3B%5Cn%26lt%3B%5C%2Fdiv%26gt%3B%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Development%20of%20a%20Bioreactor-Coupled%20Flow-Cell%20Setup%20for%203D%20In%20Situ%20Nanotomography%20of%20Mg%20Alloy%20Biodegradation%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jan%22%2C%22lastName%22%3A%22Reimers%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Huu%20Ch%5Cu00e1nh%22%2C%22lastName%22%3A%22Trinh%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Bj%5Cu00f6rn%22%2C%22lastName%22%3A%22Wiese%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Sebastian%22%2C%22lastName%22%3A%22Meyer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Jens%22%2C%22lastName%22%3A%22Brehling%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Silja%22%2C%22lastName%22%3A%22Flenner%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Johannes%22%2C%22lastName%22%3A%22Hagemann%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Maximilian%22%2C%22lastName%22%3A%22Kruth%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Lidia%22%2C%22lastName%22%3A%22Kibkalo%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Hanna%22%2C%22lastName%22%3A%22%5Cu0106wieka%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Birte%22%2C%22lastName%22%3A%22Hindenlang%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Marta%22%2C%22lastName%22%3A%22Lipinska-Chwalek%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Joachim%22%2C%22lastName%22%3A%22Mayer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Regine%22%2C%22lastName%22%3A%22Willumeit-R%5Cu00f6mer%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Imke%22%2C%22lastName%22%3A%22Greving%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Berit%22%2C%22lastName%22%3A%22Zeller-Plumhoff%22%7D%5D%2C%22abstractNote%22%3A%22Functional%20materials%20feature%20hierarchical%20microstructures%20that%20define%20their%20unique%20set%20of%20properties.%20The%20prediction%20and%20tailoring%20of%20these%20require%20a%20multiscale%20knowledge%20of%20the%20mechanistic%20interaction%20of%20microstructure%20and%20property.%20An%20important%20material%20in%20this%20respect%20is%20biodegradable%20magnesium%20alloys%20used%20for%20implant%20applications.%20To%20correlate%20the%20relationship%20between%20the%20microstructure%20and%20the%20nonlinear%20degradation%20process%2C%20high-resolution%20in%20situ%20three-dimensional%20%283D%29%20imaging%20experiments%20must%20be%20performed.%20For%20this%20purpose%2C%20a%20novel%20experimental%20flow%20cell%20is%20presented%20which%20allows%20for%20the%20in%20situ%203D-nano%20imaging%20of%20the%20biodegradation%20process%20of%20materials%20with%20nominal%20resolutions%20below%20100%20nm%20using%20nanofocused%20hard%20X-ray%20radiation%20from%20a%20synchrotron%20source.%20The%20flow%20cell%20setup%20can%20operate%20under%20adjustable%20physiological%20and%20hydrodynamic%20conditions.%20As%20a%20model%20material%2C%20the%20biodegradation%20of%20thin%20Mg-4Ag%20wires%20in%20simulated%20body%20fluid%20under%20physiological%20conditions%20and%20a%20flow%20rate%20of%201%20mL%5C%2Fmin%20is%20studied.%20The%20use%20of%20two%20full-field%20nanotomographic%20imaging%20techniques%2C%20namely%20transmission%20X-ray%20microscopy%20and%20near-field%20holotomography%2C%20is%20compared%2C%20revealing%20holotomography%20as%20the%20superior%20imaging%20technique%20for%20this%20purpose.%20Additionally%2C%20the%20importance%20of%20maintaining%20physiological%20conditions%20is%20highlighted%20by%20the%20preliminary%20results.%20Supporting%20measurements%20using%20electron%20microscopy%20to%20investigate%20the%20chemical%20composition%20of%20the%20samples%20after%20degradation%20are%20performed.%22%2C%22date%22%3A%222023-07-26%22%2C%22section%22%3A%22%22%2C%22partNumber%22%3A%22%22%2C%22partTitle%22%3A%22%22%2C%22DOI%22%3A%2210.1021%5C%2Facsami.3c04054%22%2C%22citationKey%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fdoi.org%5C%2F10.1021%5C%2Facsami.3c04054%22%2C%22PMID%22%3A%22%22%2C%22PMCID%22%3A%22%22%2C%22ISSN%22%3A%221944-8244%22%2C%22language%22%3A%22%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222024-01-25T12%3A27%3A58Z%22%7D%7D%5D%7D

Dora, J., Möddel, M., Flenner, S., Reimers, J., Zeller-Plumhoff, B., Schroer, C. G., Knopp, T., & Hagemann, J. (2025).

Model-based autofocus for near-field phase retrieval.

Optics Express,

33(4), 6641–6657.

https://doi.org/10.1364/OE.544573

Kirchner, F., Wieland, D. C. F., Irvine, S., Schimek, S., Reimers, J., Aversa, R., Boubnov, A., Lucas, C., Flenner, S., Greving, I., Marinho, A. L., Wong, T. M., Willumeit-Römer, R., Eschke, C., & Zeller-Plumhoff, B. (2025).

An ontology-based description of nano computed tomography measurements in electronic laboratory notebooks: from metadata schema to first user experience (arXiv:2501.07398). arXiv.

https://doi.org/10.48550/arXiv.2501.07398

Dora, J., Flenner, S., Lopes Marinho, A., & Hagemann, J. (2024). A Python framework for the online reconstruction of X-ray near-field holography data (1.3.1). Zenodo. https://doi.org/10.5281/zenodo.14024980

Dora, J., Möddel, M., Flenner, S., Schroer, C. G., Knopp, T., & Hagemann, J. (2024).

Artifact-suppressing reconstruction of strongly interacting objects in X-ray near-field holography without a spatial support constraint.

Optics Express,

32(7), 10801–10828.

https://doi.org/10.1364/OE.514641

Reimers, J., Trinh, H. C., Wiese, B., Meyer, S., Brehling, J., Flenner, S., Hagemann, J., Kruth, M., Kibkalo, L., Ćwieka, H., Hindenlang, B., Lipinska-Chwalek, M., Mayer, J., Willumeit-Römer, R., Greving, I., & Zeller-Plumhoff, B. (2023).

Development of a Bioreactor-Coupled Flow-Cell Setup for 3D In Situ Nanotomography of Mg Alloy Biodegradation.

ACS Applied Materials & Interfaces,

15(29), 35600–35610.

https://doi.org/10.1021/acsami.3c04054